Universal Link Gateway

Universal Link Gateway

Overview

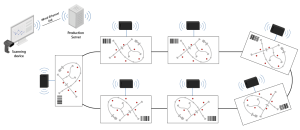

One of the most important aspects of the manufacture of wiring harnesses is to have under control all the steps of the production process: from the manufacture of subassemblies to the assembly of the harness in the conveyor, from the ultrasonic welding, torque and tightness of grommets to all the steps of the wiring harness test such as electrical test, vision, clips test, and finally the processes of visual and dimensional inspection and packaging.

Our UniversalLink Gateway (ULG) is a low-cost, highly flexible hardware equipped with software that bridges the gap between different suppliers’ equipment, communication protocols, and the process control system (ERP).

With ULG, wiring harness manufacturing is 100% monitored throughout the production process, ensuring total control and traceability.”

Features

Cost effective: Accurate entrance Price and scalable according the process needs.

Free OS Licenses: Free OS licenses and maintenance.

Flexibility: Easy to use in combination with any other device. Operating

system LINUX.

Connectivity: Wireless, Ethernet, Bluetooth, RS232, USB, HDMI, GPIO, others.

Customizable: Easy to adapt to complex environments such as KSK manufacturing system and connection between machines from third party companies.

Peripherals: Possibility to connect all type of peripherals such as: monitors, keyboard, mouse, printers, scanners, cameras, others

Use Case

Matching station: A matching station is intended to make the matching between main harness and one of its subassemblies. The goal of this application is to assure that the proper harness subassembly is mounted in the carrousel board.

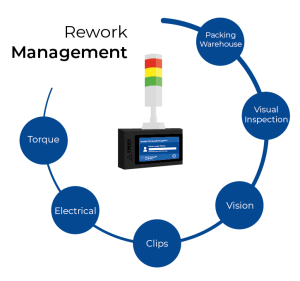

Rework Control: The rework station is a special station for fixing defective products outside the regular production line, which can be sent from any production step or warehouse and then sent back to the next step after repairs.

Link 3rd party device: ULG links a connectivity limited leak test device with the production server.

Visual Inspection: ULG obtains from the server the list of visual inspections to be performed

Special Production Steps: ULG can be used to manage the communication between a high variety of stations and the server, such as: Packaging Station, Warehouse to rework, Foaming stations, Dispatch…

Visual indications in conveyor: To guide the operator in the routing of harness at rotary line, by switching on LEDs based on branch length.