Overview

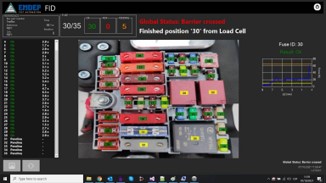

FID is a system that fully automates the assembly of fuses and relays into the boxes. It can operate with several fuse boxes simultaneously, even once already connected to the full wire harnesses.

Main Characteristics

Thanks to the force and distance measurement we assure the highest quality on the insertion process.

All the quality collected data is fully traceable. The system can generate automatic reports to be shared with the OEMs about each assembled fuse / relay box.

Automatic Optical inspection by camera system is performed for each component

Possibility to assembly several fuse boxes simultaneously.

Easy re-programing of insertion steps on engineering change request.

Easy to adapt the equipment to new fuse boxes just updating the holder and feeding trays when there are new components.

Compact machine reducing space in production line.

Possible to communicate to ERP or KSK data system to create testing references in real time and upload test results.

Before it is inserted.