High Voltage

High Voltage

Overview

We produced our first High Voltage tester with the irruption of the e-Mobility concept in the automotive industry in 2009. Since then, we delivered more than 200 High Voltage tester and other e-Mobility solutions such as Assembly and tester for Junction Boxes, Cable leakage tester, connector assembly and verification. Our solutions include different technologies and products such as: cable tester, screwing machine, vision inspection, leak tester, robotic automation solution, scanning and printing, etc.

Main features

- Up to 6000VDC/4200VAC

- Insulation resistance & dielectric withstand

- Continuity test integrated

- Expandable test points

- Light barrier protection

- Kelvin measurement

- Leak and flow test

- Functional test

- LIN comunication

- Scanner & printer support

- Unlimited test programs

- Graphical programming Method

- Test sequence fully Customizable

- Connection to ERP system

- Traceability data available

Fast Testing

Our smart testing algorithm allows to parallelize the HV measurement.

This feature decreases dramatically the number of measures to be performed to assure the correct isolation in all the cable and in consequence, it reduces the testing time.

65% time saving for one cable with 3 cores vs 1 shield.

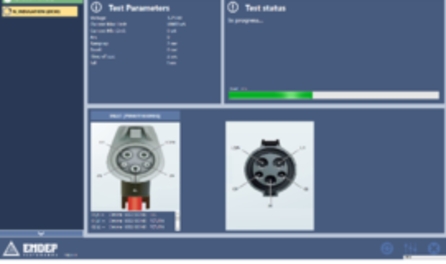

Optimized Software Interface

Graphical, modern looking, simple and powerful interface to be programmed easily even for non high computer skilled users.

The graphical interface also shows to the operator clear and graphical messages about the test progress and status, indicating the connector and cable related in each step.

Traceability & Connectivity

All our equipment are saving historic test data and results. The format, way and path where this data is saved can be customized to be adapted for local resources, network paths or remote database connections.

It is also implemented the communication with any ERP system to download in real time the test data and upload the test results when the test is finished.

Applications

Specific solutions for aerospace, military and train industry

High Voltage test for e-mobility wiring harness industry

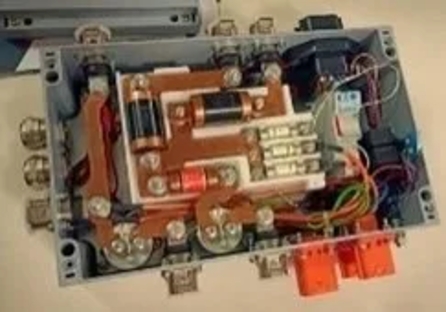

Assembly and test of Junction Box and Power distribution boxes

Smart Test Solutions for e-Mobility

Test Adapters

Leak and flow test for connector and cables

High Current

Functional Test

Unshielded Cables

Test Adapters

Our test adapters are designed to assure an optimal electric contact with the lowest effort for the operator. At same time, they offer the possibility to check all electrical, physical and functional characteristics of the connector, among others:

– Secondary lock, CPA, levier, cover presence and position

– Colour of cable, housing or components

– Coding of connector

– Pin straightness

– Presence of seals, air leakage by vacuum or pressure

More than 100.000 designs for general automotive connectors and 200 specific for e-Mobility have been already designed and produced.

Leak and flow test for connector and cables

A common situation in e-Mobility cables is the fact that the air is passing through the connector terminals and flooding the inner space in the cable.

In this situation, to check it in a controlled and measured way makes possible to assure that the complete cable is totally tight and there is no any minimal air leakage in any part of the connector neither along the cable.

In that way, defects such as missing seals or punctures in the cable can be detected.

High Current

High current test allows to detect deffects in welding, weak contacts or broken strands.

This is a complex test where the design of the adapter requires an special concept and technology.

The quality of the contact between the adapter and the terminal is a critical point.

Our high current adapters are designed to offer the best contact conditions allowing to perform test up to 300 amps in the safer and more reliable manner.

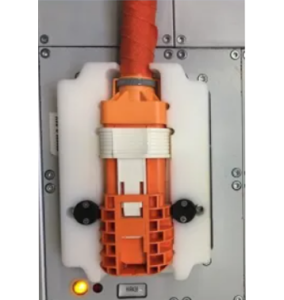

Functional Test

To assure the correct function of the locking system existing on each charging Inlet it’s necessary to perform a functional test by activating and deactivating the engine integrated in the lock mechanism.

Our adapters perform this operation while the test system controls the position and resistance value in real time.

New charging Inlets include LIN comunication for advanced smart operations to control the status LED, Cover status, lock position etc. our tester communicates with the LIN device to activate each function and assure it works properly.

Unshielded Cables