Overview

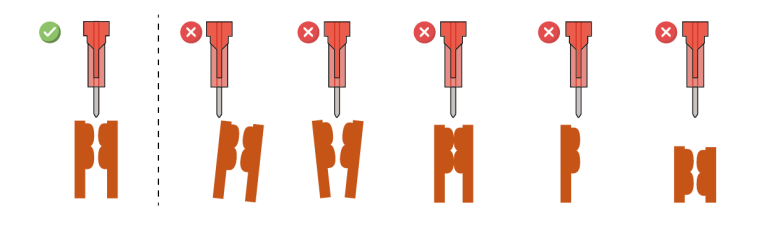

The CID (Component Insertion Device) system performs the automatic insertion of fuses and relays into the fusebox. It monitors and registers the insertion depth and force along all the process, preventing wrong insertion due to problems in terminals or component.

Main Characteristics

Controlled fuses and relays insertion

Height and insertion force fully configurable

Integrated vision test to assure position and values of fuses/relays

Full traceability of insertion height and force…for each fuse

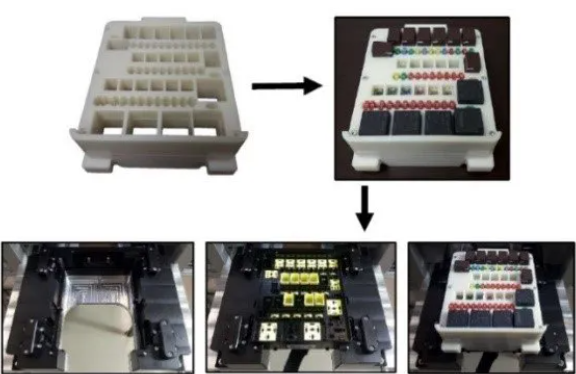

With the use of mask to preload the fuses ( OPTIONAL )

Option of integrated tool change to select different tips for different components

Technical Data

Technical Specifications | 180N | 500N |

|---|---|---|

Insertion Mode | 1 finger Ø5mm (options avail.) | Trough mask + 1 finger Ø5 Change tool possible |

Insertion speed | 1.2seg/fuse | 1seg/fuse |

Max. Insertion force | 180N | 500N |

Working area | 380x300x100mm (XYZ axis) | 425x320x100mm (XYZ axix) |

Shipping weight | 154Kg. | 280Kg. |

External dimensions | H=165mm L=845mm W=652mm | H=785mm L=1026mm W=850mm |

Options

Fuse Mask

Tool to load fuses outside machine to improve takt time.

Tool Finger

Chance to change multiple finger sizes according to fuses and relays sizes/shapes.